Professional and high-quality metal alloys, ceramic products and concrete additives | RBOSCHCO

PRODUCT PARAMETERS

Description

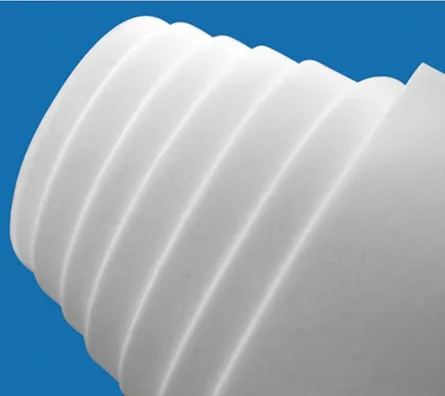

Overview of Aerogel Insulation Sponge

TR-S collection aerogel insulation wool series products, is a with low density, low thermal conductivity of the flexible thermal insulation material, formed by the hydrophobic silica aerogel combined with the substrate, is very suitable for narrow space insulation needs, can be in the complex surface of the flexible mounting.

(Aerogel Insulation Sponge)

Features of Aerogel Insulation Sponge

Aerogel insulation sponge is a light, porous material known for excellent heat resistance. Its structure has tiny air pockets that stop heat from moving through conduction, convection, and radiation. Even though it’s very light (sometimes lighter than air), it stays strong and keeps its shape under pressure. This sponge repels water but still lets air escape, which stops moisture buildup. It’s versatile and easy to cut, making it good for strange forms. It’s risk-free to use, does not melt, and lasts a very long time in challenging conditions. Individuals utilize it in spaceships, structures, and electronics cooling. It’s costly to make, but brand-new methods are attempting to bring costs down. On the whole, it combines great performance with sensible uses, offering green methods to conserve energy.

Specifications Table of Aerogel Insulation Sponge

| Product Model | TR-S |

| Product Thickness | 0.6-4 mm |

| Product Tolerance | 0.2-0.5 mm (Tolerance increases with thickness) |

| Product Width | 1200 mm |

| Appearance | White Roll Material |

| Thermal Conductivity (25°C) | 0.012~0.018 W/(m·K) |

| Product Density | 100 ± 30 kg/m³ |

| Operating Range | -50~230°C |

| Surface Property | Hydrophobic |

| Flame Retardancy | UL94-V0 |

| Dielectric Strength | >4 kV/mm |

Applications of Aerogel Insulation Sponge

Aerogel insulation sponge has many uses. In the aerospace field, it helps keep spacecraft components at the right temperature. The sponge’s light weight is a big plus here as it doesn’t add much extra mass. For buildings, it’s great for insulation. You can put it in walls and roofs. It cuts down on heat loss in winter and heat gain in summer, so it saves on energy bills. In electronics, it helps cool sensitive parts. Since it stops heat well, it stops overheating. Even though it can be costly, its good performance makes it worth using in these important areas.

Company Profile

RBOSCHCO is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality chemicals and Nanomaterials. The company export to many countries, such as USA, Canada, Europe, UAE, South Africa,Tanzania,Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech Republic, Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand, Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a leading nanotechnology development manufacturer, RBOSCHCO dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are interested, please send an email to: sales1@rboschco.com

Payment Term

T/T, Western Union, Paypal, Credit Card etc.

Shipment Term

By air, by sea, by express, as customers request.

5 FAQs of Aerogel Insulation Sponge

Q1:What is an aerogel insulation sponge made of?

Aerogel insulation sponge is made from a gel where the liquid part is replaced with air. The base materials can be silica, carbon, or other substances. For example, silica-based aerogels are common. They start as a liquid mixture of chemicals like silicon alkoxides. These react and form a gel, which is then processed to remove the liquid and leave behind the porous, sponge-like aerogel structure.

Q2:How effective is it at insulating?

It’s highly effective. Aerogel has a very low thermal conductivity. The tiny pores in the sponge trap air, and the air is a poor heat conductor. This stops heat from moving through conduction, convection, and radiation. In fact, it can be up to 10 times better at insulating than traditional insulation materials like fiberglass. It can really cut down on heat loss or gain in buildings, electronics, and more.

Q3:Is it easy to install?

Yes, it’s relatively easy. Aerogel insulation sponge is flexible. You can cut it to fit different shapes and sizes. In building applications, you can slip it into wall cavities or between roof rafters. In electronics, it can be molded around components. Its light weight also makes handling and installation simpler compared to heavier insulation materials.

Q4:Is it resilient?

Aerogel insulation sponge is rather durable. It stands up to moisture well due to the fact that it’s hydrophobic. So, it will not obtain harmed by water. It can likewise hold up against normal temperature adjustments without breaking down. Nonetheless, it’s necessary to handle it very carefully as it can be a little bit breakable. But generally, with appropriate treatment, it can last a long time in many applications.

Q5:Why is it so pricey?

The production procedure is complex and expensive. Making aerogel needs special equipment and specific chemical reactions. The drying out step, specifically, is hard. Typical drying can create the structure to collapse. So, supercritical drying out techniques are frequently used, which need expensive devices and a lot of power. Likewise, the raw products and chemicals utilized in the process contribute to the price. Yet as modern technology improves, the price may come down in the future.

REQUEST A QUOTE

RELATED PRODUCTS

Factory 99% CuO Cupric Oxide / Copper Oxide / Copper (II) Oxide CAS 1317-38-0

High Purity 99.9% Antimony Doped Tin Oxide/ATO Nano Powder CAS 128221-48-7

Solid Silica Dispersant TR-WSiOT10 Alkaline High Quality Silica Nanoparticle Dispersion

Bismuth Oxide Powder Bi2O3 Powder Price

High Quality Quartz Powder SiO2 Crystalline Powder Bulk Supply